The automotive industry’s chain of operations faced a huge disruption due to the economic slowdown of the 2020-21 fiscal year. Automakers faced multiple supply chain problems along with rising prices of materials and fuel. The market was filled with price concerns for new vehicles which impacted car sales globally. Purchase, repair and services of vehicles were all reported to have been significantly costlier than before. According to J.P.Morgan, in the U.S., the average price of a new vehicle was up 6.3% in 2021.

Original Equipment Manufacturers (OEMs) in the automotive industry reported a lack of manufacturing components due to supply chain disruptions. Even the average cost of raw materials used in the manufacturing of new vehicles has increased by 106% from $1,779 in 2020 to $3,662 per vehicle in 2022, a CNBC study claims.

According to the Japan Iron and Steel Recycling Institute, the cost of rolled steel plates of standard dimensions in January 2020 was 90 Yen/kg which is now 145 Yen/kg in 2022, 60% higher.

Even though the world’s vehicle demand has shifted towards Electric, manufacturing of Electric Vehicles has also been affected by rising costs of raw materials including lithium, nickel and cobalt.

CNBC reports an average cost of raw materials for EVs in 2020 to be $3,381 per vehicle which is now $8255 in 2022, a 144% hike.

The global shortage of Semiconductor Chips is also one of the reasons for the supply-demand imbalance in the automotive sector.

Ford disclosed a backlog of 40,000 to 45,000 unfinished vehicles in their inventory in 2022 due to supply shortages.

The recent Russia-Ukraine war has also put the world oil supply on its toes with oil price hikes going through the roof. Due to rising fuel prices, the logistics sector also faced the effect of inflation.

In the United States, depreciation of dollars against other currencies has increased the vehicle production cost by 20%.

What can automakers do to reduce car prices ?

According to a report by J.P.Morgan, vehicle prices dropped by 1.4% in September from August 2022 with a positive indication of reducing further in 2023. Automakers are facing losses due to increased costs in every aspect of manufacturing, sales and shipping; a complete reinvention of their inventory structure is needed.

Inventory, components and raw materials cost about 57%the overall vehicle cost, which can be reiterated to reduce the market price of vehicles.

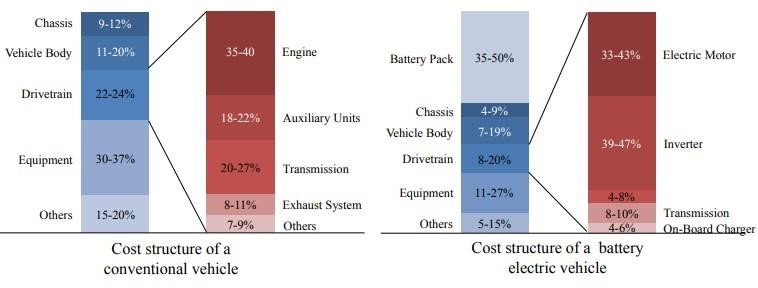

With the supply chain not operating at its full capacity and higher procurement cost of fuels, the demand for EV production was high. EVs are viable not only for vehicle owners but also for manufacturers as their component inventory requirement is significantly lower than conventional vehicles.

The cost structure of a conventional Internal Combustion Engine vehicle is vastly different than that of an Electric Vehicle as shown below :

Courtesy of Institute of Automotive Technology, Germany.

Many automakers like Tesla, Rivian and TATA have already shifted their focus on cost saving and profitability. A thorough ground level research is conducted to help make essential decisions during sourcing & manufacturing. Due to razor-thin profit margins in this industry, automakers need an effective cost saving strategy.

An “Order on Demand” approach is a viable option for carmakers to reduce their inventory costs where the production of a new vehicle starts only after the order is confirmed. This can be seen in the case of Tesla vehicles where they can be personalized and ordered online from their website.

On-demand manufacturing enables real-time adjustments and changes to the design, ensuring all design prototypes are finished as quickly as possible and completed in a controlled manner. Factories have a powerful database that allows designers to review previous adjustments, improve future components, and monitor changes to completed prototypes, which is very valuable for the automotive industry seeking rapid transformation.

GOKEN’s “Should Cost” analysis is unrivaled in the automotive industry when it comes to supplier negotiation, cost drivers analysis and cost saving potential.

Assessing the true cost of a product requires detailed diligence of material cost, manufacturing process and logistics. At GOKEN, a complete breakdown of the competition’s product cost is benchmarked. This data is used for appropriate cost saving insights and to evaluate suppliers based on selection criteria.

2022 saw car manufacturers refocusing on profitability more than stepping first into the market, GOKEN’s “Should Cost” analysis identifies cost saving potential to help make essential decisions during sourcing & manufacturing.

Goken’s amazing team is consistently putting out ideas and suggestions to reduce the manufacturing, overheads and delivery costs while focusing on quality products and profits. GOKEN supports its clients at every step of the “Should Cost” process to potentially save millions of dollars for their organization.

Connect with the Managing Director of Goken India to discuss the opportunities.

https://www.linkedin.com/in/swapnilgawade

Media Contact

Company Name: Venus Media House

Contact Person: Bhagyashree

Email: Send Email

City: Kolkata

Country: India

Website: www.venusmediahouse.com