The green and efficient cleaning of the laser cleaning machine makes it increasingly popular in diverse industries and helps it gradually replace traditional cleaning methods, such as sandblasting and acid cleaning.

The green and efficient cleaning of the laser cleaning machine makes it increasingly popular in diverse industries and helps it gradually replace traditional cleaning methods, such as sandblasting and acid cleaning.The green and efficient cleaning of the laser cleaning machine makes it increasingly popular in diverse industries and helps it gradually replace traditional cleaning methods, such as sandblasting and acid cleaning. Handheld laser cleaners are the main type of laser cleaners on the market. The handheld ones are small in size and portable coupled with the advantages of green and efficient cleaning, all of which improve convenience and effectiveness.

The green and efficient cleaning of laser cleaning machines not only means clean results, but also applying green cleaning methods during processing. Compared with wet chemical cleaning, the laser cleaner avoids the use of toxic solvents and noise. In addition, laser cleaning is gentle and is faster than other cleaning methods. These advantages have been recognized by various industries and laser cleaners are used as multi-purpose green cleaning tools.

Five applications of laser cleaning machines are as follows:

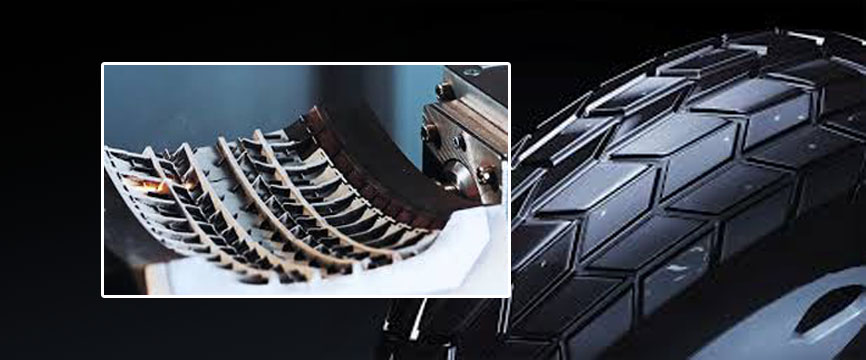

1. Aircraft old paint cleaning

In the aviation industry, the aircraft surface needs repainting after a certain period, but the old paint needs completely removing before repainting. Traditional mechanical paint removal methods are easy to damage the metal surface of aircraft, which brings potential risks to safe flight. By comparison, laser cleaning machines solve this problem, so it is widely used to clean aircraft old paint efficiently and conveniently without damage to the metal surface.

2. Building facade cleaning

More and more buildings are constructed following the rapid development of the economy. Therefore, the cleaning of building facades is an important focus nowadays. The speed of the laser cleaner is many times faster than that of conventional methods so that it can effectively clean various pollutants on many materials, such as stone, metal, and glass.

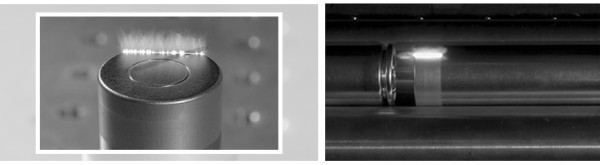

3. Electronic component cleaning

High-precision decontamination of electronic components can be achieved by the laser cleaning machine. Pins of electronic components need completely decontaminating to ensure optimal electrical contact without damage before the welding of circuit boards, which can be actualized by the laser cleaning machines with high precision, high effectiveness, and high efficiency.

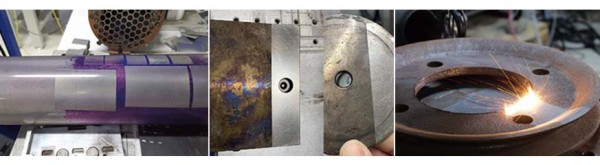

4. Precise de-esterification of precision instruments

Chemical methods are generally used to remove ester and mineral oil for lubrication and anti-corrosion on parts in the precision machinery industry, but residues are generated by these methods. In contrast, the laser cleaning machine can thoroughly remove ester and mineral oil by shock waves generated by the vaporization of oxide thin layer on parts rather than by mechanical forces, thus no residues and damage caused.

5. Nuclear power plant reactor pipeline cleaning

The laser cleaning machine is also applied to nuclear power plant reactor pipeline cleaning. Radioactive dust is removed by the high-power laser beam of optical fiber directly irradiating into reactor pipelines. This method is convenient and safe for operators because of the long-distance operation.

Laser cleaners can be used to remove residues from components or to efficiently clean paint or rust laser remover by setting other parameters. As a high-tech cleaning tool, the laser cleaner has great prospects on the market and will be applied to more industries with a demand for green and efficient cleaning in the future.

Media Contact

Company Name: LASERCLEANER

Contact Person: Kevin

Email: Send Email

Country: China

Website: https://www.lasercleaner.com/